PRODUCT INFORMATION

Pulsafeeder – XPV Dosing Machine (Dosing Pump)

- front page

- product

- Mechanical peristaltic injection

- Injection treatment

- Pulsafeeder – XPV Dosing Machine (Dosing Pump)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

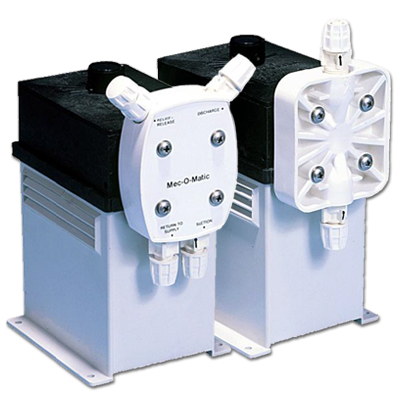

Pulsafeeder – XPV Dosing Machine (Dosing Pump)

Dosing pump (pump)/dosing machine: Two shoe blocks, mounted on a rotating wheel at a 180° angle, squeeze in turn the fluid to be pumped in the rubber hose. The squeezing of the hose by the rotating shoe creates continuous suction at the pump inlet and pushes the fluid towards the pump outlet. The pump casing contains a lubricant that reduces friction and ensures optimum pump performance with minimal maintenance. The transported liquid is only in contact with the inside of the rubber hose, so a variety of reactive fluids can be transported.

美國 Pulsafeeder company was founded in 1936, with the latest and most advanced technology to manufacture all kinds of acid and alkali resistant pumps, to meet the needs of fuel cells, solar energy systems, circuit board equipment, chemical industry, surface treatment industry, food industry, medical equipment, photo processing Ultra-clean pump required for photoresist coating, developing, stripping and etching cleaning processes such as water treatment equipment, plant factories, optoelectronic semiconductor manufacturing processes and packaging. Although the quality is already in the leading position in the world, Pulsafeeder is constantly developing a new generation of products to respond.

Established in 1976, 瑞順 Enterprise Co., Ltd. is the Taiwan general agent of American Pulsafeeder Inc. products. It has been providing high-quality pumps (pumps) for 50 years to ensure customers work safety, clean environment and save energy. In addition to the Taipei head office, 瑞順 also has service locations and parts warehouses in Changhua and the southern region, which can instantly meet customer needs.

Its performance is as follows:

Hose metering pumps are available for flow rates from 10 ml/h to 410 l/h. During use, they can withstand pressures up to 8 bar. The high-flow hoses used by the pulsafeeder convince because of their particularly outstanding durability and wide chemical compatibility.

It works as follows:

The hose, which rests on the housing, is clamped by means of a roller on the rotor. The rotational movement of the rotor moves the clamping position in the desired conveying direction of the conveying medium. When the rollers press the medium through the hose into the metering head, the hose is released again. The hose that is erected again creates a low pressure, which draws clean medium into the hose. By increasing the rotor speed, the delivery volume can be increased linearly.

Application:

• Sewage purification: metering of highly viscous media/polymer solutions

• Drinking water treatment: metered disinfectant

• Food industry: shear-sensitive media, flavors, additives

• Paper industry: dosing additives

• Cooling cycle: metering of anti-corrosion and antimicrobial agents

• Plastic production: dosing additives

• In general: chemical dosing up to 410 l/h

• Capable of conveying suspended solids commonly found in the following industries: paints, dairy and beverages, meat and fish processing, pharmaceuticals and cosmetics, wastewater and water treatment, chemical and petrochemical industries, pulp and paper, textiles, soaps and fats, construction, ceramics .

Special features:

The Pulsafeeder hose metering pump perfectly combines the advantages of a hose pump and a metering pump. So they support, for example: batch or proportional dosing. Depending on the medium, the measurement accuracy can reach ±1 %. They work as reliably as our other metering pumps, are self-priming and have no issues with venting media. Thanks to the lean tube changing process, they can be done in the shortest time and with the least amount of material input.

feature of product:

– Microprocessor management, variable speed through various external signal input

– LCD display

– Optional double-head dosing

– Low pressure/high pressure and Norprene/Fluran peristaltic hose options

– Dosing with 4-20MA, HALL Effect, dry contact, timer, etc.

Technical teaching:

Dosing pump (pump)/dosing machine: Two shoe blocks, mounted on a rotating wheel at a 180° angle, squeeze in turn the fluid to be pumped in the rubber hose. The squeezing of the hose by the rotating shoe creates continuous suction at the pump inlet and pushes the fluid towards the pump outlet. The pump casing contains a lubricant that reduces friction and ensures optimum pump performance with minimal maintenance. The transported liquid is only in contact with the inside of the rubber hose, so a variety of reactive fluids can be transported. Technical explanation

| maximum dosage | 100GPD(15.8LPH) |

| maximum speed | 65RPM |

| motor | Single-phase AC 115V 60Hz, 230V 50/60Hz |

| Peristaltic tube material | Norprene, Fluran options available |

Optional 15, 35 gallon bucket dosing