日本 Olympia Co., Ltd. has nearly 70 years of burner development and research technology, with an annual production of more than 50,000 burners, and the market share of 日本 is more than 70%. Olympia burners are widely used in Taiwan: heat transfer oil stoves, incinerators, hot blast stoves, industrial and commercial furnaces, food drying, kitchen utensils, painting, steam, die casting, ovens, ironing and other thermal industries.

The gun type (GUN TYPE) automatic burner is composed of the body and automatic control parts. It is not necessary to reorganize the pump, gas ignition, automatic control and the trouble of wiring and piping during installation. , Small horsepower, low power consumption, no noise, strong capacity, large firepower, no need to use gas ignition, using automatic computer program to control the electric eye to monitor the flame, the use of card-type maintenance is very simple. The principle of spray gun type <GUN TYPE> is to use high pressure spray, atomization can reach 99.9% complete combustion, it is not necessary to use wind pressure to blast the spray, resulting in excess air volume to take away heat loss, and can improve fuel economy.

The LT series is the standard model among many diesel series models. The combustion capacity ranges from the smallest 3L/Hr to the largest 30L/Hr, etc., for many models to choose from. In addition to the most basic ON-OFF control, the operation control also includes the electromagnetic suction type damper control developed by ourselves, and the LOW-HIGH control that changes the gas consumption by switching the air volume of the damper motor and the solenoid valve, etc. multiple choices. Besides heavy oil models, special diesel heaters for cold regions can also be installed separately. Applicable to: die casting machine, paint furnace, boiler, incinerator, fryer, dryer.

Features:

日本 original, the whole machine imported.

Stable performance and long service life.

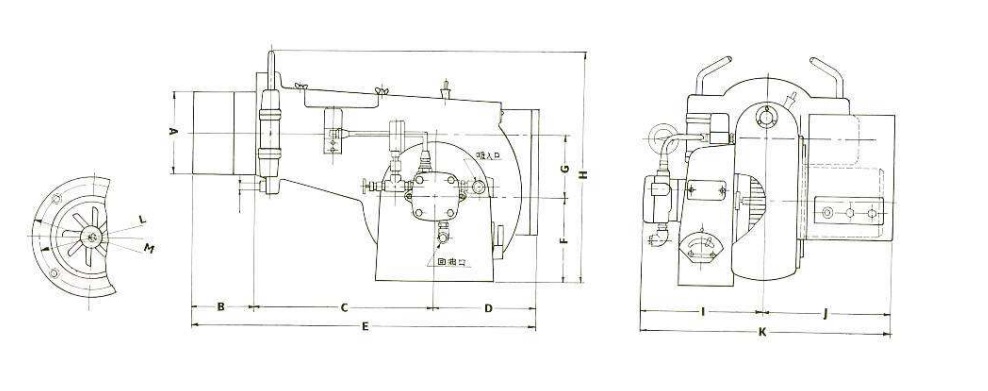

Beautiful appearance, reasonable structure, lightweight design, complete functions but not occupying space.

Fully automatic control, easy operation and installation, easy maintenance.

Rotating flange design for easy installation and maintenance.

There are protection measures such as wind pressure, gas pressure switch and flame monitoring.

Applicable to all kinds of boilers, heating furnaces, hot blast stoves, forging furnaces, incinerators.

High-pressure atomization method can effectively achieve complete combustion and reduce fuel costs

High-voltage ignition method, and equipped with flame monitoring device, safe and reliable

_S.jpg)

_S.jpg)

_S.jpg)

_S.jpg)

_S.jpg)

_S.jpg)