PRODUCT INFORMATION

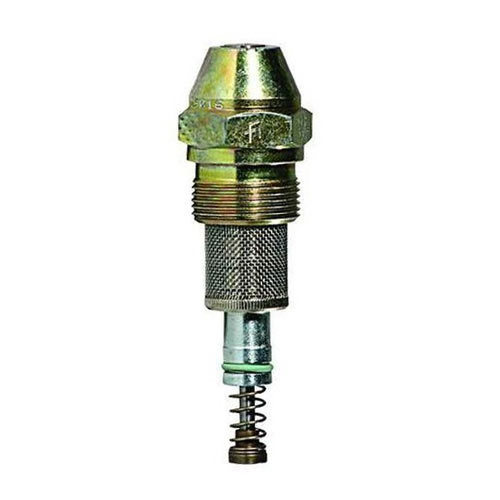

Delavan nozzle

- front page

- product

- heat treatment

- oil nozzle

- Delavan nozzle

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

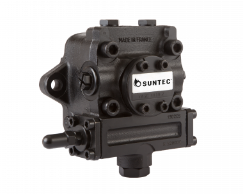

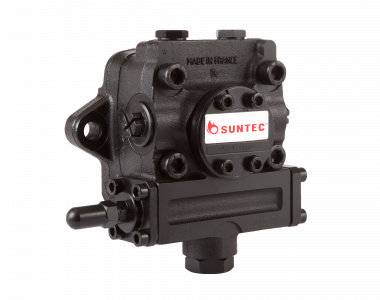

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

Delavan nozzle

美國 Delavan Original

Delavan pressure fuel injectors have several important responsibilities, not only to provide accurate fuel quantity, but also to atomize the fuel into an extremely

Small droplets, and at the same time make the atomized droplets produce a specific spray angle, so that the fuel can be completely burned by 100%. As the fuel is atomized into tiny droplets,

Each droplet is tightly covered by air, and the excellent ratio of air to fuel is an important factor that enables the burner to achieve complete combustion.

The atomization process of oil can be divided into two stages to illustrate the first stage: the fuel is pressurized by the pump and then delivered to the nozzle, when the fuel passes through the filter on the nozzle.

Filter, the filter will block the impurities in the fuel, ensure the cleanliness of the fuel and prevent the nozzle from being blocked, and the filtered fuel will be pushed to the injector.

Tangent dose slot in mouth. The tangent dose slot has two important functions, the first of which is to precisely control the amount of fuel passing through the nozzle, the tangent dose slot

Its width and depth, about 1/40 the size of an adult human hair, are so tiny that they can only be seen through a microscope. The second function of the tangent dose tank is to guide the fuel

Introduced to the rotation chamber of the nozzle, the fuel immediately produces a high-speed rotation. Stage 2: High-speed rotation of fuel in the shape of a hollow tube resembling a tornado

The shape, after being pushed, comes into contact with the wall of the nozzle and is sprayed towards the nozzle. After the fuel leaves the nozzle, it will continue to rotate, but only for a very short period of time.

within the distance. When the fuel leaves the nozzle a distance of about 0.4 mm, centrifugal force separates the swirling fuel and causes the droplets to immediately form and atomize.

美國 Delavan original technical explanation

| factory | model | spray angle | Type |

| Hago | SS | 45 / 60 / 80 | |

| Monarch | HO | 60 | |

| Danfoss | H | 60 / 80 | |

| Delaval | B | 60 | |

| Monarch | BPS | 45 / 60 | proportional |

| Delaval | FEB | 45 / 60 | |

| Weishaupt | W | 50 |