heat treatment

Thermal energy materials

water treatment

water quality material

Injection treatment

injection material

After sending your product inquiry list, our relevant business unit will contact you as soon as possible

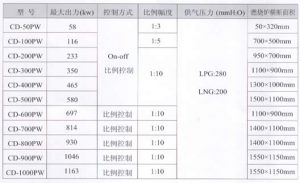

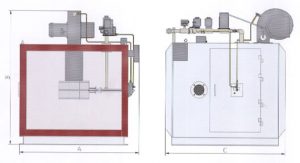

日本 Olympia Co., Ltd. has nearly 70 years of burner development and research technology, with an annual production of more than 50,000 burners, and the market share of 日本 is more than 70%. Olympia burners are widely used in Taiwan: heat transfer oil stoves, incinerators, hot blast stoves, industrial and commercial furnaces, food drying, kitchen utensils, painting, steam, die casting, ovens, ironing and other thermal industries.

Features:

日本 original, the whole machine imported.

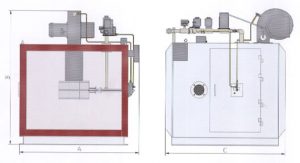

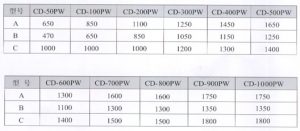

The burner is placed in the combustion chamber to make full use of the space.

Simple operation, full automatic control can be realized.

So parts are easy to check and maintain.

It adopts premixed ignition mode, equipped with flame combustion detection, gas pressure switch and air pressure switch.

The standard flow rate design in the combustion chamber is 7~11m/s, and the flow rate can be designed according to the needs.

Applicable: food drying, coating drying, fiber drying