PRODUCT INFORMATION

Ultraviolet sterilizer (UV, 70~800 GPM)

- front page

- product

- water treatment

- UV ultraviolet sterilizer

- Ultraviolet sterilizer (UV, 70~800 GPM)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

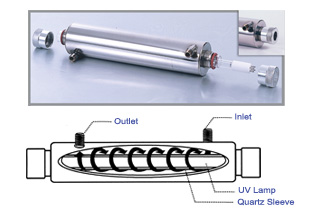

Ultraviolet sterilizer (UV, 70~800 GPM)

The TOC content can be reduced using activated carbon filtration and RO systems or DI systems; however, for substantial TOC reduction, UV light is usually used as the last step in the treatment process. This is a simple and very effective method.

In recent years, UV technology has been widely used in water treatment in various industries, such as microelectronics, pharmaceuticals, power generation, food and beverages, cosmetics, aquaculture, direct drinking water, etc. Ultraviolet technology can be used not only for disinfection but also for TOC (Total Organic Carbon) reduction and ozone removal. Recent developments in UV technology have greatly improved the efficiency and performance of TOC degradation.

In semiconductor manufacturing, even trace amounts of TOC in rinse water can cause serious problems for semiconductor chip production. Smaller and smaller microchips have put forward stricter requirements for ultrapure water, and have posed greater challenges to water purification system design and facility engineering. Because TOC can cause defects on the surface of the silicon wafer, resulting in short-circuiting of the electrodes. In addition, organic matter provides microorganisms with a large number of required nutrients to promote their growth and reproduction.

Some TOC levels can be reduced using activated carbon filters and reverse osmosis (RO) systems or deionization (DI) systems; however, for substantial TOC reduction, UV light is usually used as the last step in the treatment process. This is a simple and very effective method. The 185 nm radiation of the low-pressure quartz UV lamp generates hydroxyl (OH) radicals, which can oxidize most organic matter to carbon dioxide (CO2) and water (H2O). like: TOC+UV185nm→CO2+H2O

Specification Table: