PRODUCT INFORMATION

Customized series of container solutions (reduce on-site installation costs)

- front page

- product

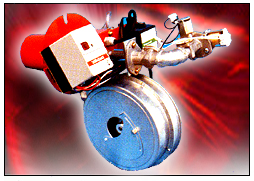

- steamer

- heat treatment

- Customized series of container solutions (reduce on-site installation costs)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

Customized series of container solutions (reduce on-site installation costs)

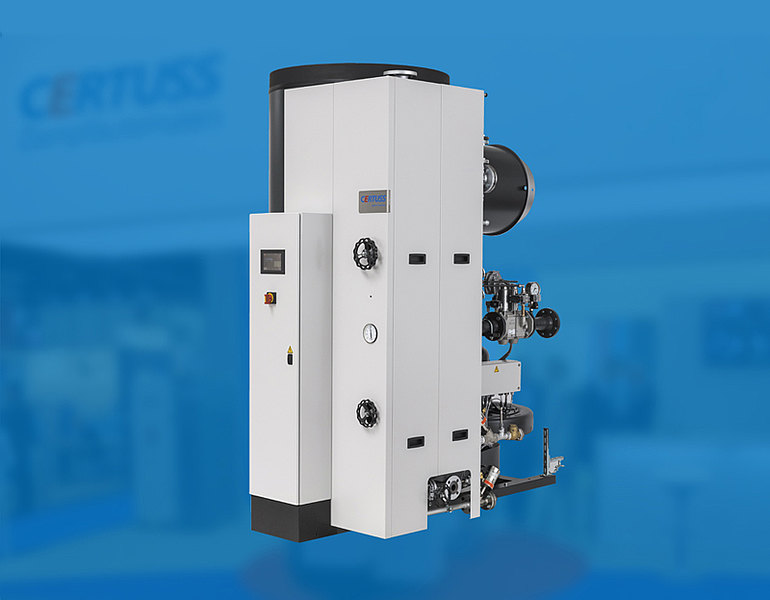

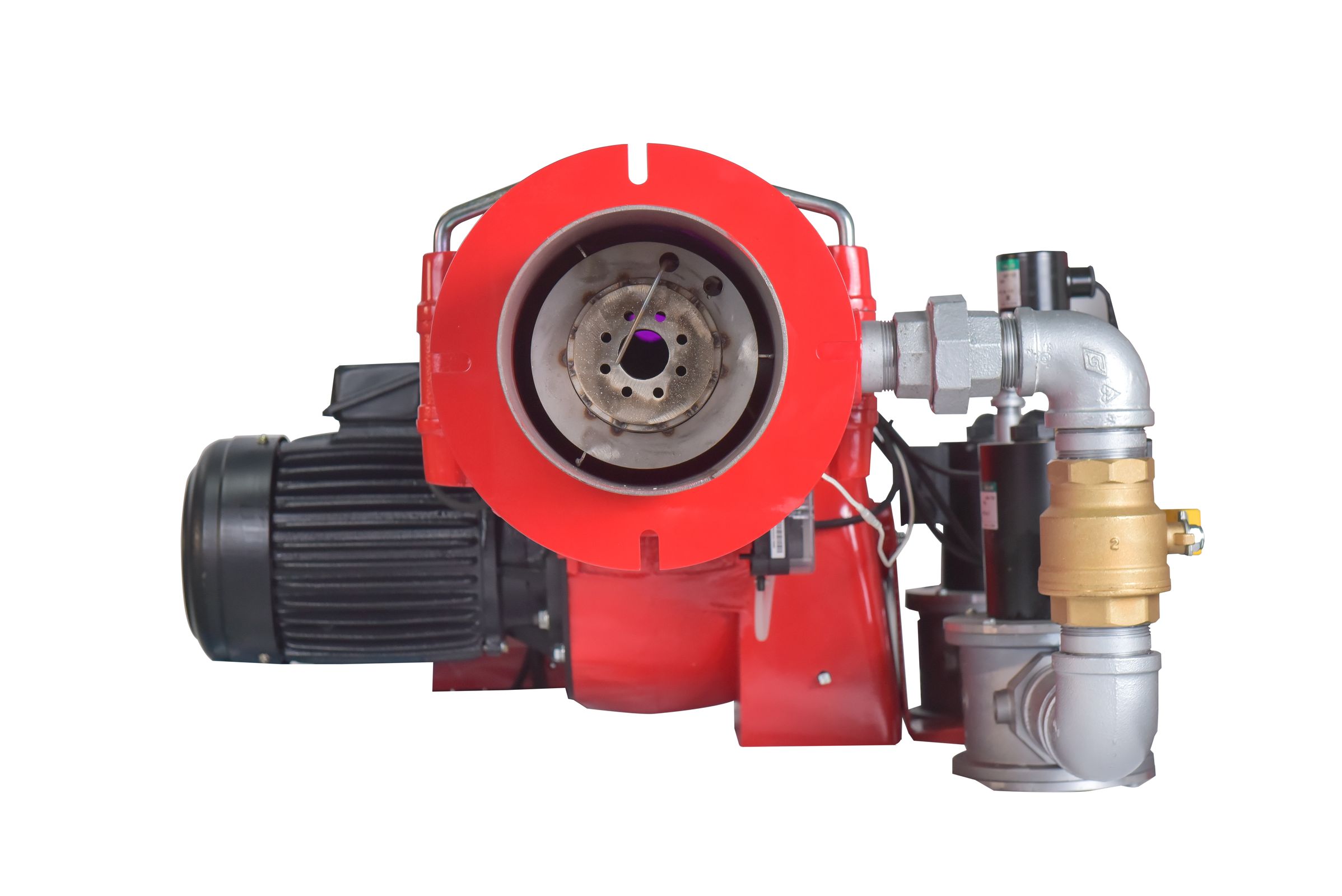

德國 Certuss Original

CERTUSS self-contained container units are our solution to facilitate the need for isolation from the rest of the plant. It contains all the components needed to operate the entire steam system. Steam is ready to use in less than 5 minutes after the main services are connected and commissioned. The all-inclusive unit is flexible and can be positioned permanently and temporarily. Depending on the problem, we can take over all or part of the installed steam system. Should you choose to outsource to another company, we can provide consultation and supervision for your container unit.

Main functions include

– Container module interior fully illuminated

– Container modules are fully heated inside to protect against harsh weather conditions

– All piping within the container module is fully laid to specification

– All components are fully wired inside the container module

– Conduct full electrical, mechanical and steam testing before sending to your production site

– All internal piping systems of the container modules are fully insulated to the required specifications

– Lined with stainless steel walls and fully insulated

– Connection points on the outside of the container module, at an agreed site location for easy service connection (by the installer)

– Central control panel and switchboard inside the container module ready for on-site power connection (by installer)

– Color coded according to the European standard of your choice

– Has a ventilation system to comply with current code standards for boiler rooms

Advantage

- save space

– Flexible and easy placement according to requirements

– Removal of the requirement for a separate boiler room

– Allows customers to take full advantage of valuable ground handling space

– Maintenance work access is equipped

– Reduce on-site installation costs

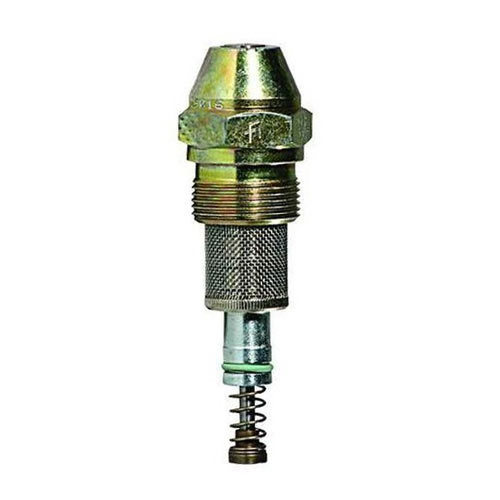

德國 Certuss original technical explanation

-可調壓差式 蒸汽專用.jpg)

-可調壓差式.jpg)

-固定壓差式 水、油、空氣.jpg)

.jpg)

.jpg)

.jpg)

.jpg)