PRODUCT INFORMATION

Clark CLACK pouring funnel (opening: 2.5 inches, 4 inches, 6 inches) (suitable for most filter media: quartz sand, activated carbon, resin, manganese sand, fine sand, gravel)

- front page

- product

- FRP pressure tank

- water treatment

- Clark CLACK pouring funnel (opening: 2.5 inches, 4 inches, 6 inches) (suitable for most filter media: quartz sand, activated carbon, resin, manganese sand, fine sand, gravel)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

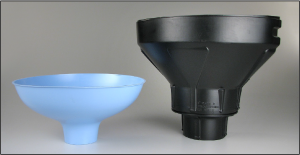

Clark CLACK pouring funnel (opening: 2.5 inches, 4 inches, 6 inches) (suitable for most filter media: quartz sand, activated carbon, resin, manganese sand, fine sand, gravel)

Clark Clack美國 funnel, imported from Wisconsin, is specially designed for users in the 美國 market. Clack Technology Department specializes in the sliding characteristics of various filter materials, and designs the best funnel angle, wire shape, and groove height to guide the filter materials into the barrel smoothly. The neck of the funnel has a well-designed exhaust port, which allows the air trapped in the FRP pressure barrel to be discharged naturally when the filter material is poured in. Clack actually observed ergonomics and designed an oval opening design to provide an extra-wide pouring area. At the same time, the molded handle design increases the convenience of force.

Features:

(1) Solid material:

and Clack The same material as a salt water bucket, high-density blow moldingHigh polyethylene for excellent strength and durability.

(2) ventilation design:

Funnel neck vent grooves to let the air out of the barrel.

(3) Tenon design:

The funnel neck tenon design allows the funnel to be installedFRPbucketIt snaps into position and is stable and stable when pouring into the filter material.

(4) Universal size:

funnel2.5", 4", 6" Design, suitable for all kinds of barrels.

What is an FRP resin barrel?

FRP resin barrel, also known as Fiberglass Reinforced Plastic barrel, is a storage and transportation container with a strong and durable structure. These barrels are widely used in chemical, food, pharmaceutical, electronics and other industries because of their corrosion resistance, high strength, and lightweight properties.

Advantages of FRP resin barrels

- Strong corrosion resistance: FRP resin barrels can resist the erosion of many chemical substances and are especially suitable for storing corrosive liquids such as acids and alkalis.

- Lightweight and high strength: Compared with traditional metal barrels, FRP resin barrels are lighter in weight but higher in strength, making them easier to handle and operate.

- long life: FRP resin barrels have good aging resistance, long service life, and can maintain good physical properties for a long time.

- good thermal stability: This material has high thermal stability and can be used normally in a wide temperature range.

- Flexible design: FRP resin barrels can be designed and manufactured according to needs to meet the needs of different uses and specifications.

Application areas of FRP resin barrels

- Chemical Industry: Used to store and transport various chemical reagents and raw materials to ensure safety and stability.

- Food Industry: Suitable for storing edible oil, beverages, etc., non-toxic and odorless, complying with food grade standards.

- Pharmaceutical Industry: Used to store medicines and raw materials to prevent contamination and ensure medicine quality.

- it: Used as a storage container for cleaning fluid, electrolyte, etc. in the electronic manufacturing process.

- Environmental protection industry: Used in wastewater treatment, exhaust gas purification and other fields to exert its anti-corrosion and durability properties.

How to choose FRP resin barrel

When purchasing FRP resin barrels, you need to consider the following factors:

- Purpose requirements: Select the appropriate FRP resin barrel according to the materials being stored or transported to ensure that it can meet actual needs.

- Standard sizes: Choose the appropriate capacity and size to ensure convenience and efficiency in use.

- Quality Assurance: Choose products with quality assurance to ensure the durability and safety of FRP resin barrels.

- After-sales service: Choose a supplier that provides comprehensive after-sales service so that problems encountered during use can be solved in a timely manner.

in conclusion

FRP resin barrels have become an important storage and transportation tool in all walks of life due to their excellent performance and wide application prospects. During the purchase and use process, choosing the right product and paying attention to the correct usage method can maximize its advantages and improve work efficiency and safety.

To learn more about FRP resin barrels, welcome to contact our professional team, we will provide you with the best quality products and services.

Clark Clack美國 funnel, imported from Wisconsin, is specially designed for users in the 美國 market. Clack Technology Department specializes in the sliding characteristics of various filter materials, and designs the best funnel angle, wire shape, and groove height to guide the filter materials into the barrel smoothly. The neck of the funnel has a well-designed exhaust port, which allows the air trapped in the FRP pressure barrel to be discharged naturally when the filter material is poured in. Clack actually observed ergonomics and designed an oval opening design to provide an extra-wide pouring area. At the same time, the molded handle design increases the convenience of force. Technical explanation