PRODUCT INFORMATION

Clark CLACK activated carbon filter (cooling water tower bypass filtration)

- front page

- product

- water treatment

- Carbon filter (removes odor and residual chlorine)

- Clark CLACK activated carbon filter (cooling water tower bypass filtration)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

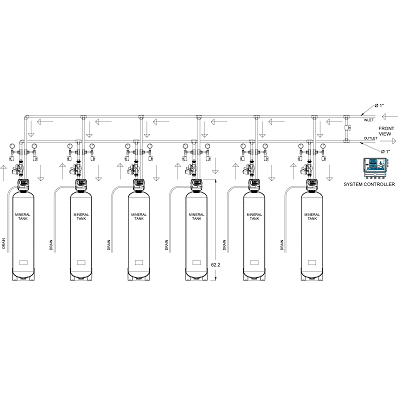

CMT series Clark CLACK activated carbon filter (cooling water tower bypass filtration)

No need for long-distance pipeline excavation/embedding/backfilling, eliminating the need for a large-scale water purification plant. Quick-release maintenance design reduces service costs.

5 major features:

(1) System features:

When the filter material is backwashed, the second clean water source is automatically switched to perform backwashing

(2) Service features:

Quick-release maintenance design reduces service costs

(3) Customer group protection:

The blue light control valve can input your company name and service phone number by yourself (the system will automatically display your company service phone number)

(4) Backwash control:

The flow mode automatically detects the total flow and automatically regenerates after reaching the

7-day mode (Cycle setting: Monday to Sunday)

28-day mode (cycle setting: every 1 day to every 28 days)

5) Provide peer applications:

Industrial sewage treatment

Laundry factory sewage treatment

Factory sewage does not meet the discharge standard to improve engineering application

Cooling tower side flow filtration: the best solution to improve efficiency and save energy

Cooling water towers play a key role in modern industry, from air conditioning systems to large industrial equipment. The stable operation of cooling water towers directly affects the performance of the entire system. However, cooling tower water quality management is often overlooked, which can lead to equipment damage and reduced energy efficiency. In this article, we will delve into Cooling water tower side flow filtration The benefits and how it can effectively improve water tower performance and save energy.

Why does cooling water tower need side flow filtration?

The working principle of the cooling water tower is to remove the heat from the equipment through the water circulation system. During this circulation process, the deterioration of water quality may cause many problems. Common pollutants in cooling water include dust, sand, algae, and various chemical components dissolved in the water, which may form sediments in the pipes and reduce cooling efficiency.

Cooling water tower side stream filtration (Side Stream Filtration)It is a water quality management method for cooling water circulation systems. It bypasses a part of the cooling water into the filtration system to filter out impurities and pollutants in the water, thereby improving water quality, reducing sedimentation, and ultimately improving the efficiency of the entire cooling system.

Advantages of side stream filtration

1. Improve equipment efficiency:By filtering impurities in the cooling water, it avoids the formation of scale or sediment inside the pipes and ensures the normal operation of the heat exchanger. This not only improves cooling efficiency but also reduces energy consumption, thereby lowering operating costs.

2. Extend equipment life:Sediment and scale can cause wear or blockage of key components of the cooling tower. The side-stream filtration system can effectively reduce the occurrence of these problems and extend the service life of the equipment.

3. Reduce maintenance costs:Cooling towers without side-stream filtration require frequent shutdowns for cleaning and maintenance, which adds additional operating costs. Side-stream filtration greatly reduces the cleaning frequency of the cooling tower, saving maintenance time and costs.

4. Environmental benefits:Sidestream filtration also helps reduce water waste. When the quality of cooling water is improved, the frequency of discharges can be significantly reduced, saving water and reducing the use of chemicals.

How to choose a cooling water tower bypass filtration system?

Choosing the right sidestream filtration system depends on several key factors:

1. Filtering accuracy:Different application scenarios have different requirements for filtration accuracy. It is usually necessary to select an appropriate filter based on the size of particles in the water.

2. Water flow:The flow rate of side flow filtration is usually 5%-10% of the total cooling tower circulating water. Therefore, the overall water flow rate of the cooling tower needs to be considered when selecting a filtration system to ensure that the filter can handle the side flow requirements.

3. Filtration technology:Currently, there are a variety of filtration technologies on the market, such as sand filtration, fiber filtration, disc filtration, etc. Each technology has its own advantages and disadvantages. The most appropriate filtration solution needs to be selected based on specific needs.

4. Maintenance convenience:Filter maintenance is also an important consideration. Choosing a system that is easy to maintain can reduce operational interruptions and ensure long-term stable operation of the system.

Common sidestream filtration technologies

1. Sand filter

Sand filtration is a traditional filtration technology that uses natural sand as the filter medium to effectively remove large particles of impurities. Sand filters usually require periodic backwashing to remove filtered particles.

2. Fiber filtration

Fiber filters use fiber bundles to capture suspended solids in the water, which is suitable for higher-precision filtration needs and can achieve finer particle filtration effects.

3. Disc filter

Disc filtration is a technology that combines high-efficiency filtration with automatic backwash for applications that require continuous filtration without interrupting the flow of water.

in conclusion

The cooling water tower side flow filtration system is an effective solution to improve cooling water quality, extend equipment life, and reduce operating costs. Choosing appropriate side-stream filtration technology and configuring it reasonably according to the specific needs of the cooling tower can greatly improve the stability and efficiency of the overall system. Faced with increasingly stringent environmental protection requirements and pressure for energy conservation and emission reduction, side-stream filtration systems provide enterprises with an economical and efficient solution.

If you are looking for ways to improve cooling tower performance or want to learn more about Cooling water tower side flow filtration solutions, please feel free to contact us, we will provide you with professional technical support and suggestions.

Technical teaching: