PRODUCT INFORMATION

CLACK industrial water softener (electrolytic disinfection)

- front page

- product

- Water softener (calcium and magnesium ion removal)

- water treatment

- CLACK industrial water softener (electrolytic disinfection)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

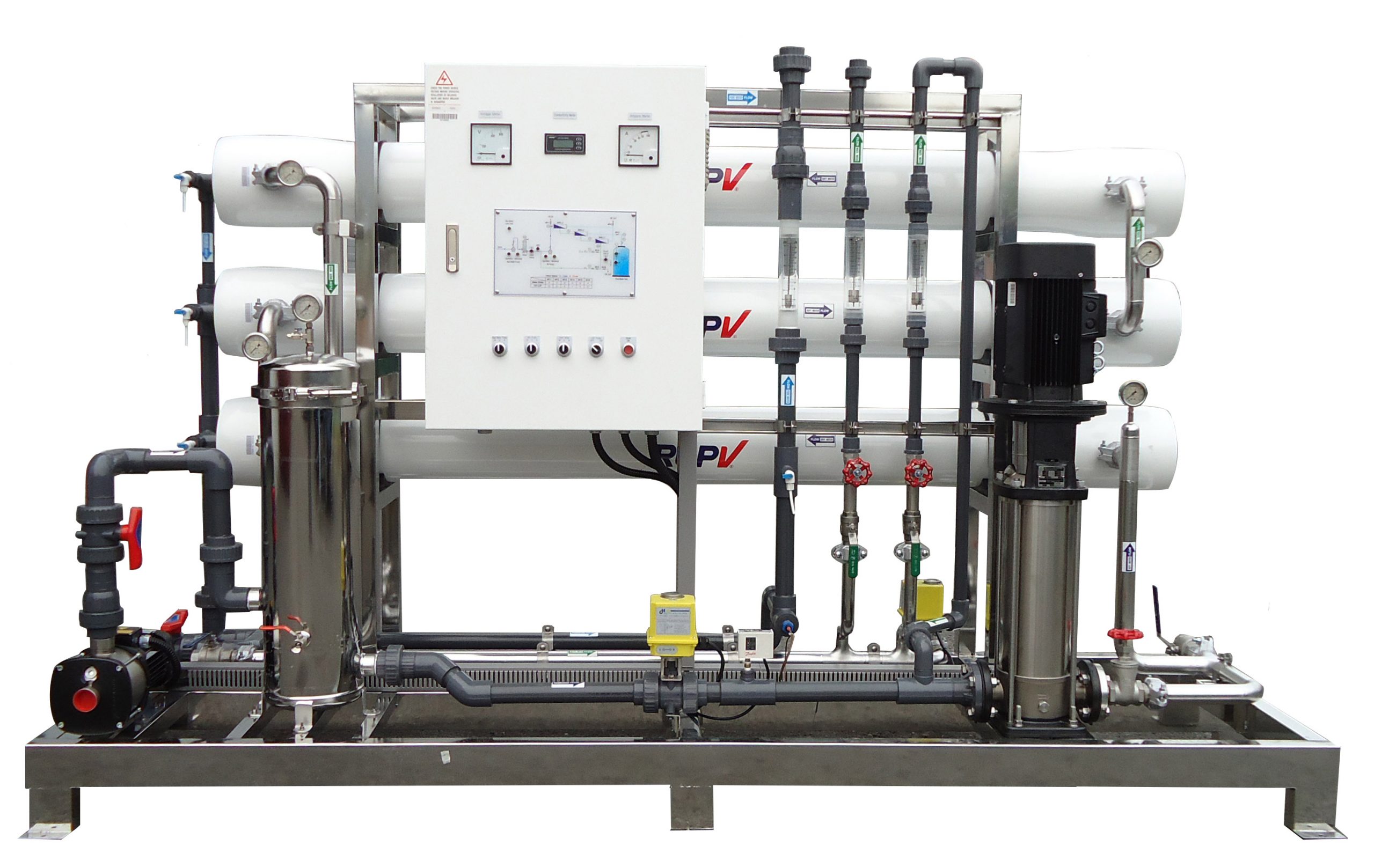

- RO water purifier

- Pre-backwash filter

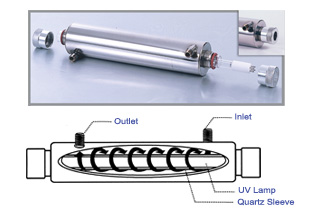

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

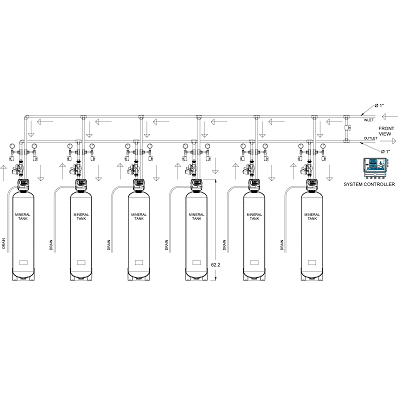

SAN series CLACK industrial water softener (electrolytic disinfection)

Most of the resin pollution sources are organic matter in the water, resulting in a decrease in the exchange volume, prolongation of the regeneration and washing time, darkening of the resin color, deterioration of the effluent quality, and acidification of the pH value of the water quality. This equipment can automatically electrolytic disinfection of the whole machine, reduce organic pollution, and effectively disinfect and sterilize the body.

5 major features:

(1) Regeneration control:

Flow mode (automatic regeneration after the total flow is detected automatically)

7-day mode (cycle setting: Monday to Sunday)

28-day mode (cycle setting: every 1 day to every 28 days)

(2) Salt bucket replenishment:

Preset replenishment time length mode

Set the salt supplement weight mode each time

(3) Salt storage barrels:

Wet Salt Storage Mode

Dry Salt Storage Mode

(4) Customer group protection:

The blue light control valve can input your company name and service phone number by yourself (the system will automatically display your company service phone number)

(5) Provide peer advantages:

One backup and one use type JDS water softener (during resin regeneration, the supply of softened water is uninterrupted)

Electrolytic disinfection type SAN water softener (using electrolytic brine to produce sterilization effect)

Ozone disinfection type OZN carbon filter (using ozone kit to produce disinfection effect)

In-tank aeration type STM iron remover (using the inner aeration kit to save the cost of the aeration tower)

Special CMT sand filter for sewage treatment (automatically converts the second clean water source to perform backwashing)

CKT water softener for waste water recovery (automatic recovery of salt-free waste water for reuse)

Multi-valve integrated special network water softener

What is an industrial water softener?

An industrial water softener is a type of water treatment equipment designed for industrial use. It is used to remove hardness ions (such as calcium and magnesium) from water to prevent scaling problems inside pipes and equipment. This kind of equipment is widely used in various industrial fields, such as electric power, pharmaceuticals, food and beverages, chemical industry, and automobile manufacturing, etc., aiming to improve equipment efficiency, extend equipment life, and ensure product quality.

Working principle of industrial water softener:

Industrial water softeners mainly use ion exchange technology to remove the hardness of water by exchanging sodium ions in the resin bed with calcium and magnesium ions in the water. When hard water flows through the resin bed, calcium and magnesium ions are captured by the resin and release sodium ions, softening the water. Over time, the resin becomes saturated with hardness ions and requires a regeneration process (usually using brine) to restore its ion exchange capabilities.

Why Choose Industrial Water Softener?

1. Improve equipment efficiency: Softened water reduces scaling in pipes and equipment, thereby improving heat exchange efficiency and overall operating efficiency.

2. Extend equipment life: By preventing scaling and corrosion, industrial water softeners can significantly extend the life of boilers, cooling towers, water heaters and other equipment.

3. Reduce maintenance costs: Reduce scaling and corrosion problems, reducing equipment maintenance frequency and repair costs.

4. Improve product quality: In pharmaceutical, food and beverage and other industries, softened water can improve product quality and ensure compliance with production standards.

How to choose the right industrial water softener?

The following factors should be considered when choosing a suitable industrial water softener:

1. Treatment capacity: Choose a water softener with appropriate treatment capacity based on industrial needs to ensure that it can meet peak water consumption.

2. Regeneration efficiency: Choose a water softener with efficient regeneration capacity to reduce salt and water consumption and reduce operating costs.

3. Durability and stability: Choose equipment with solid materials and stable operation to ensure long-term use.

4. Brand and after-sales service: Choose well-known brands and suppliers that provide good after-sales service to ensure the quality and technical support of the equipment.

Use and maintenance of industrial water softeners:

1. Regular regeneration: According to water quality and usage conditions, resin is regenerated regularly to maintain its optimal ion exchange capacity.

2. Check the equipment: Regularly check the operating status of the water softener to ensure there is no water leakage or abnormal noise from the equipment, and check whether the control valves and pipes are normal.

3. Clean the resin bed: Clean the resin bed as needed to prevent the accumulation of contaminants from affecting the exchange effect.

4. Maintenance records: Establish detailed maintenance records to record each regeneration, inspection and repair situation so that problems can be discovered and solved in a timely manner.

Summarize:

Industrial water softeners play an important role in various industrial applications, effectively improving equipment efficiency, extending equipment life, and reducing maintenance costs. Choosing the right industrial water softener and performing proper maintenance can bring significant benefits to your production operation. If you are looking for a high-quality industrial water softener, our product will be your ideal choice. We provide various types and specifications of industrial water softeners to meet different needs. Welcome to buy!

Technical teaching: