PRODUCT INFORMATION

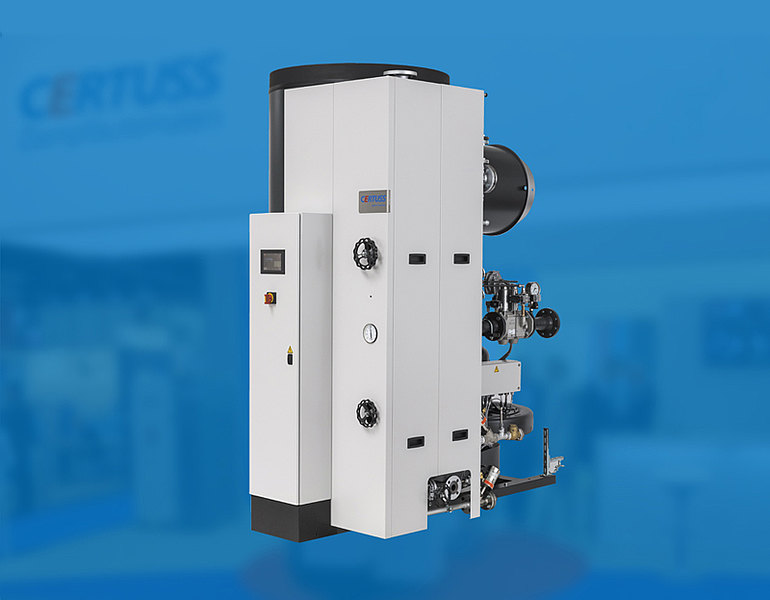

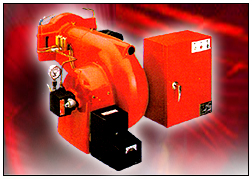

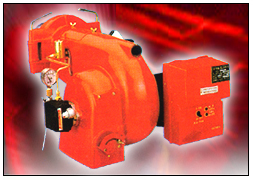

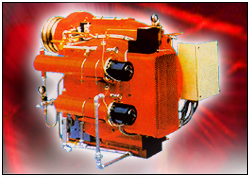

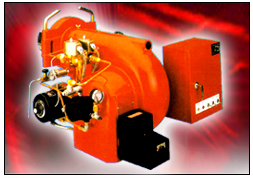

ATS series flue gas circulating burner (150~1040 kW)

- front page

- product

- smoke circulation

- heat treatment

- ATS series flue gas circulating burner (150~1040 kW)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

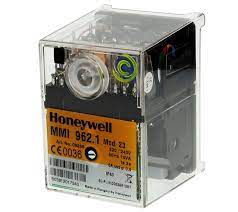

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

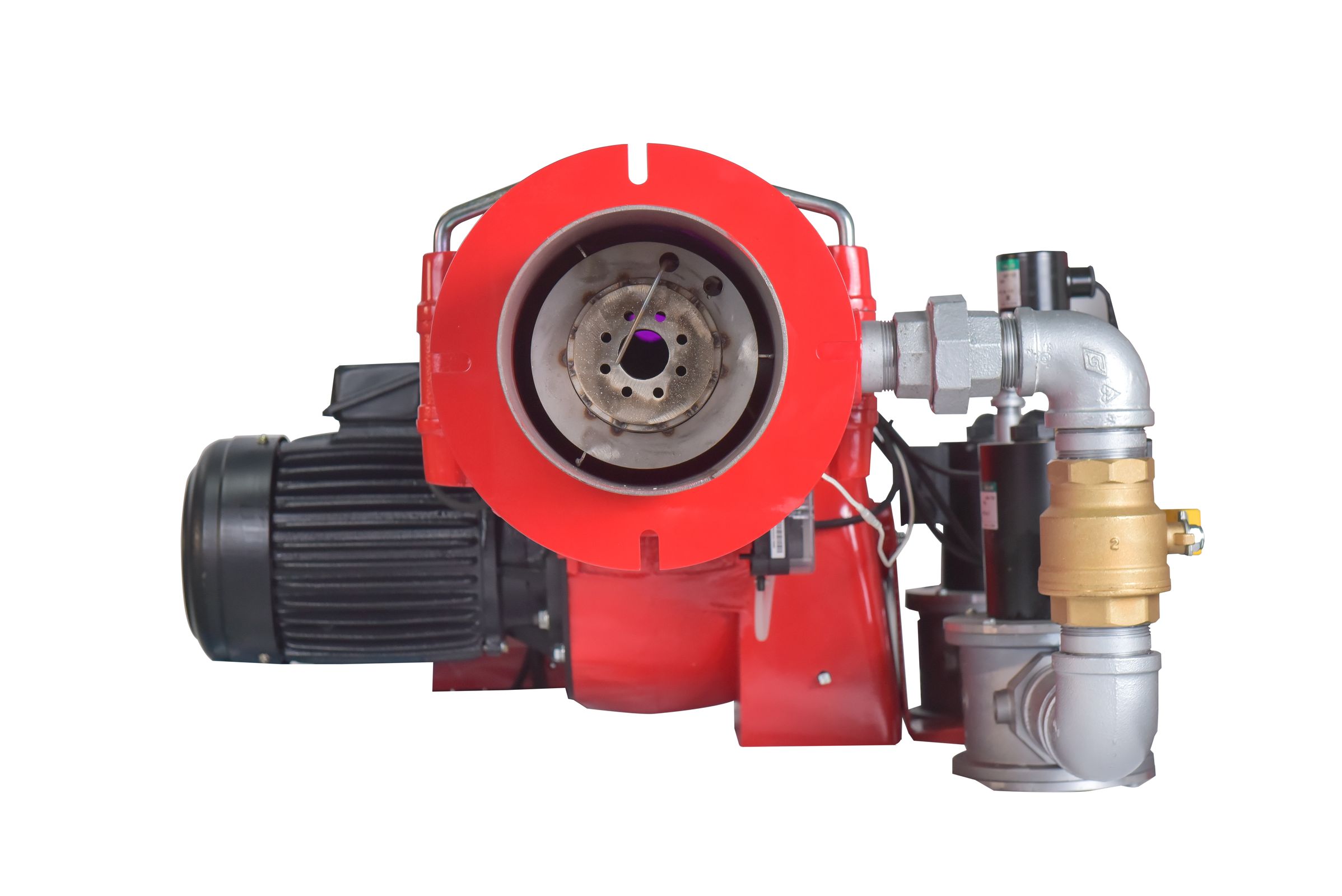

ATS series flue gas circulating burner (150~1040 kW)

日本 Olympia Original

1. Low nitrogen gas burner

2. Digital combustion management system, two-stage progressive/proportional operation

3. Flue gas external circulation system, which mixes part of the flue gas with combustion-supporting air and sends it to the combustion chamber for combustion. The mixed combustion-supporting air can reduce the temperature and oxygen concentration in the combustion chamber and effectively inhibit the generation of NOx.

4. Multiple nozzles, distributed combustion, to prevent the flame from being too concentrated and causing high oxidation reaction

5. Three servo motors are used to precisely control the ratio of combustion air volume, gas volume and flue gas volume.

6. Use a flange and a high temperature heat-resistant insulation pad to connect and fix with the boiler

7. Two-phase motor drives the fan

8. UV flame detector to detect flame

9. Standard configuration of electrical protection class IP40

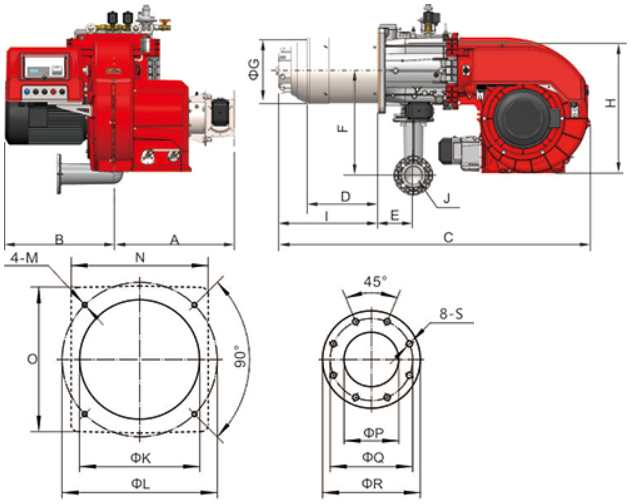

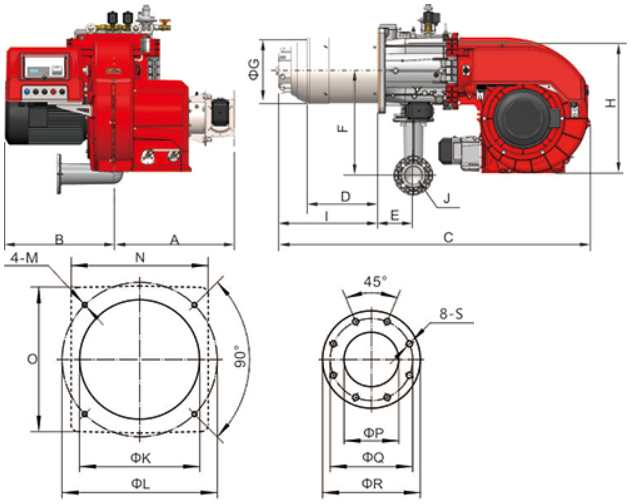

日本 Olympia Original Dimensions

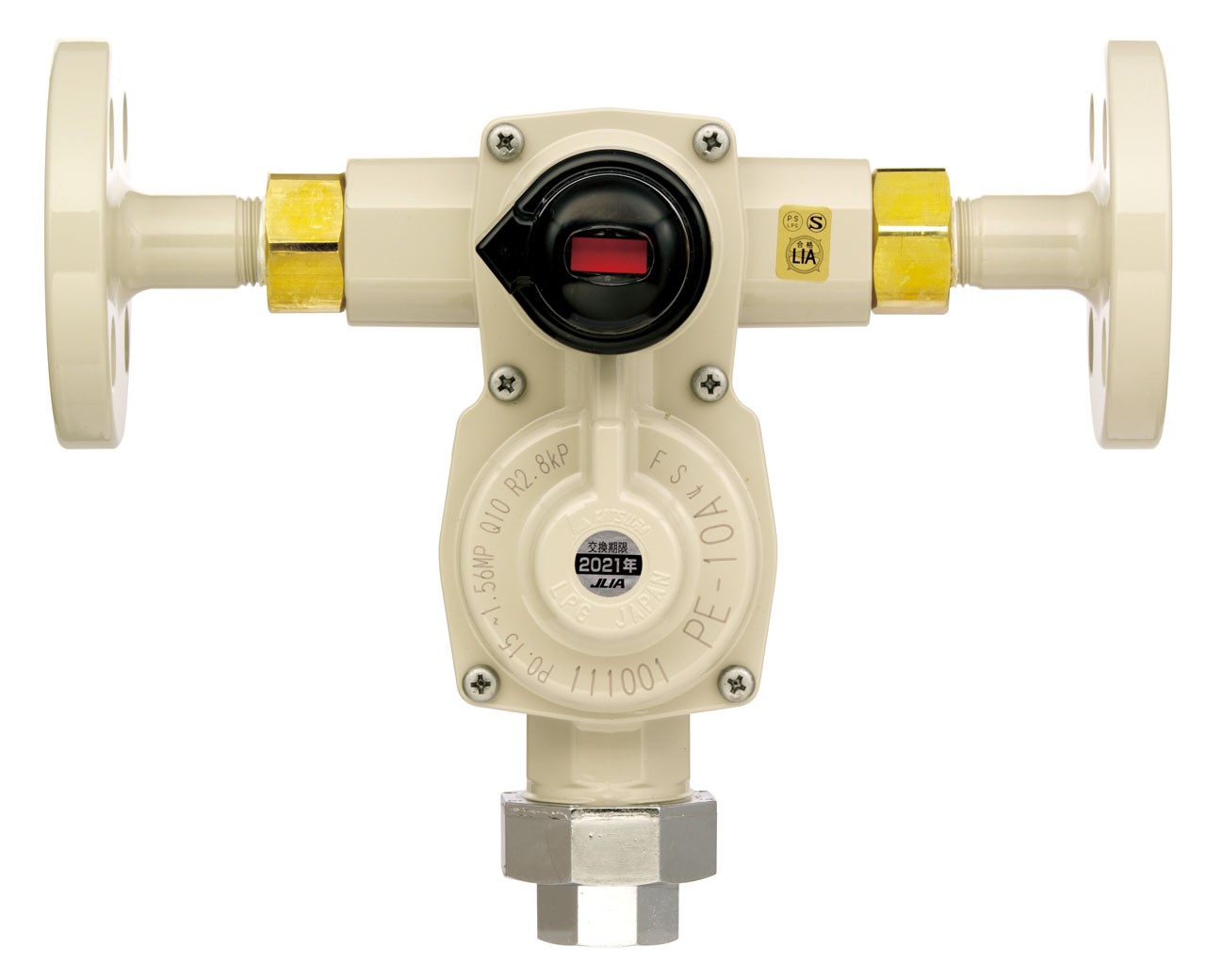

-可調壓差式 蒸汽專用.jpg)

-可調壓差式.jpg)

-固定壓差式 水、油、空氣.jpg)

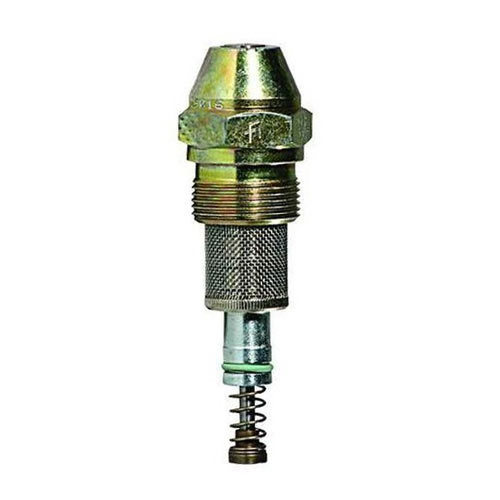

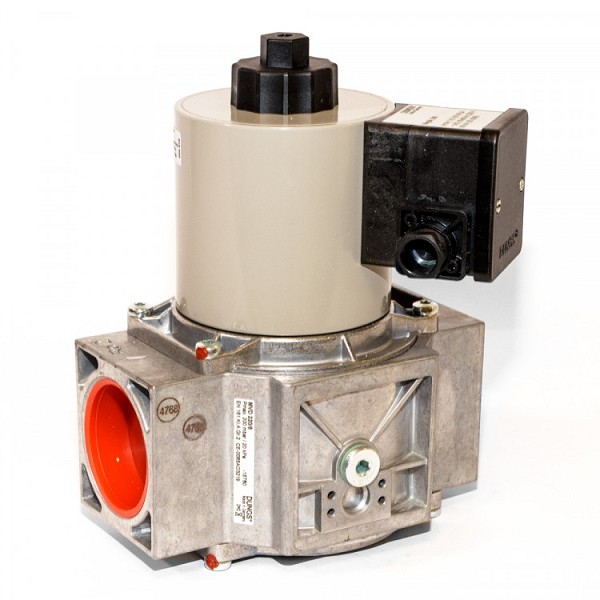

.jpg)

.jpg)

.jpg)

.jpg)