PRODUCT INFORMATION

ATS series low nitrogen burner (1200~6250 kW)

- front page

- product

- low nitrogen combustion

- heat treatment

- ATS series low nitrogen burner (1200~6250 kW)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

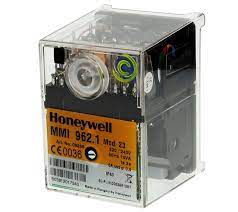

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

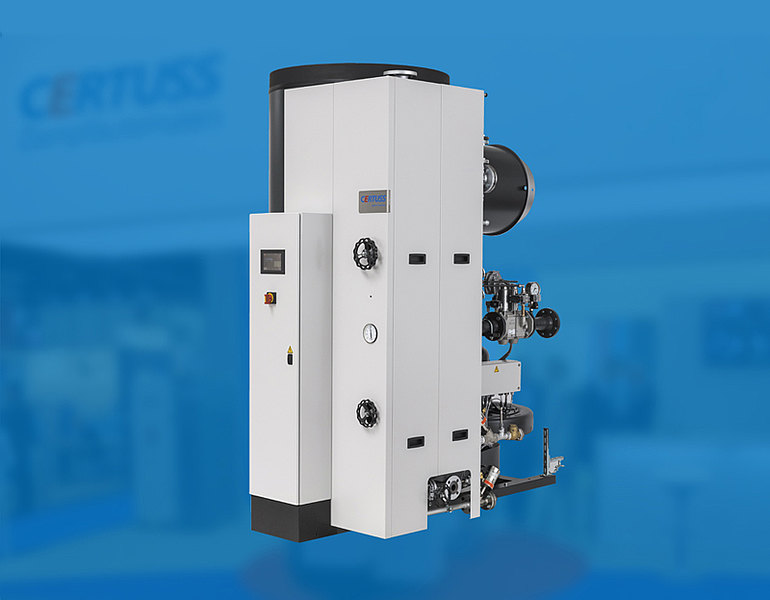

ATS series low nitrogen burner (1200~6250 kW)

日本 Olympia Original

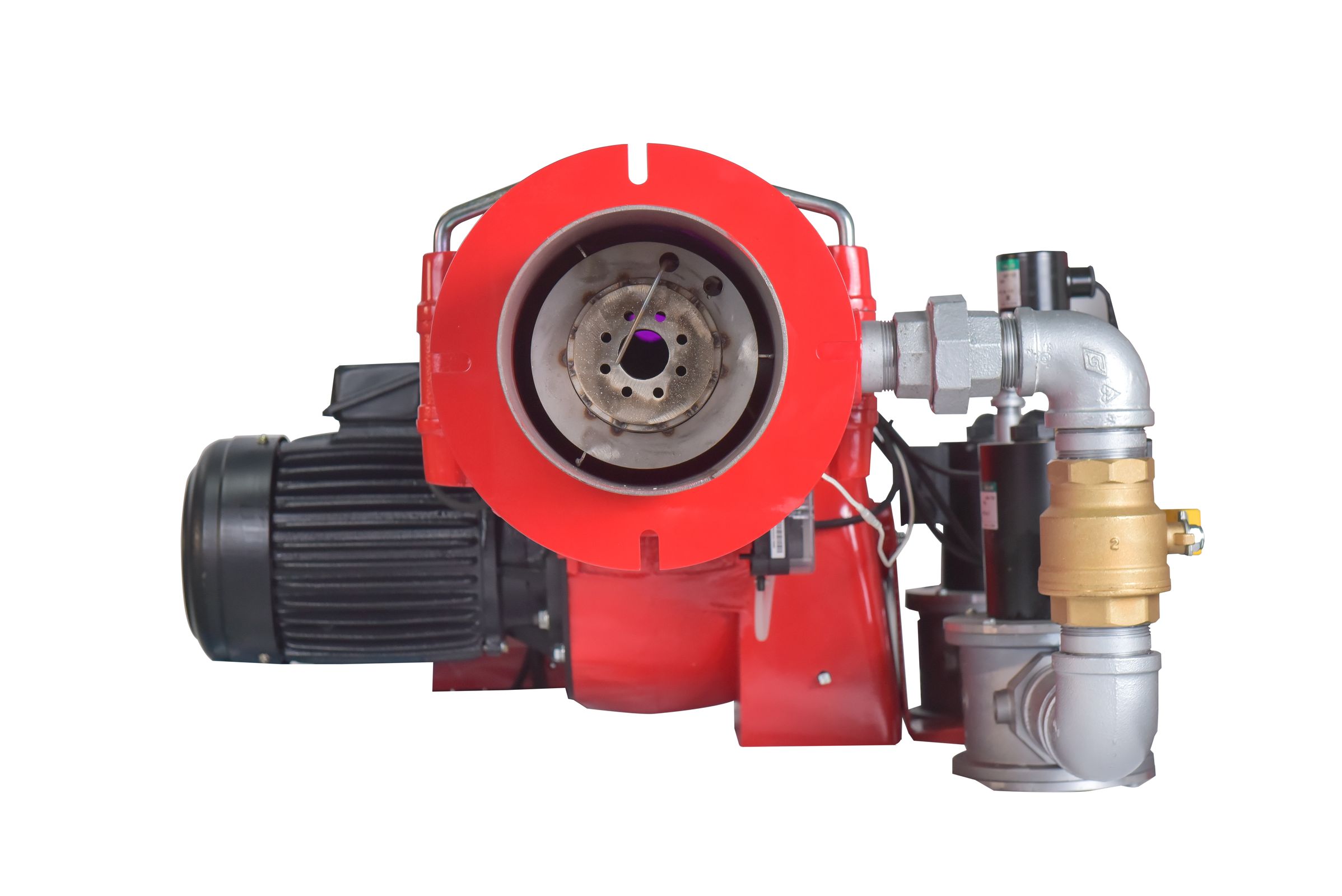

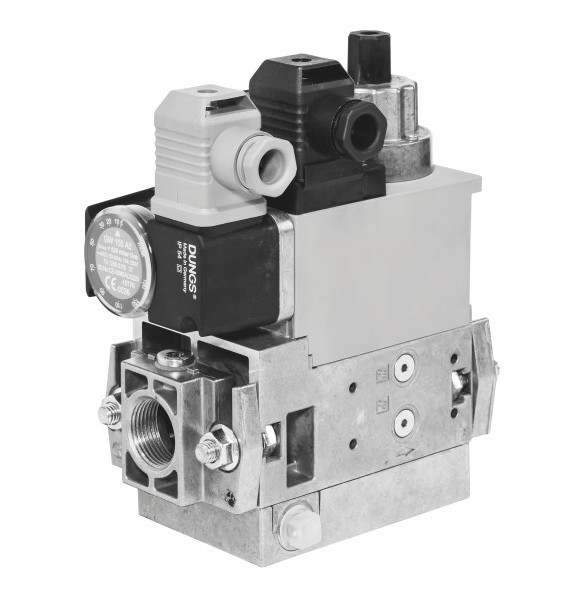

1. Low nitrogen gas burner

2. Two-stage progressive/proportional operation

3. Multiple nozzles, distributed combustion, to prevent the flame from being too concentrated and causing high oxidation reaction

4. By adjusting the combustion air and the combustion head, the best combustion efficiency can be obtained

5. Hinged connection, can be opened naturally left and right, easy maintenance

6. Use servo motors to adjust the minimum and maximum air flow in the first and second stages; when the burner is paused, the damper is closed to reduce heat loss in the furnace

7. Servo motor with cam can adjust the supply of air and fuel at the same time

8. Use a flange and high temperature heat-resistant insulation pad to connect with the boiler

9. Combustion air inlet with flow adjustment

10. Two-phase motor drives the fan

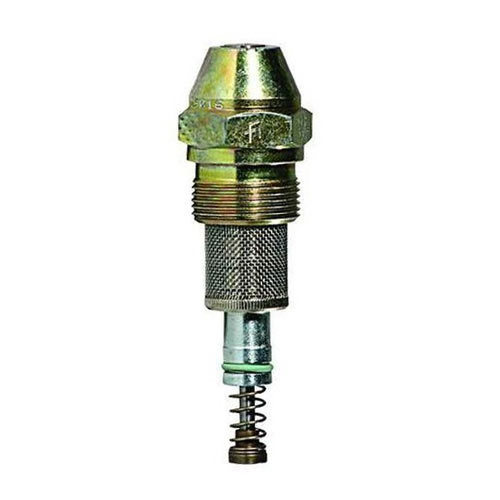

11. Ionization shock detection flame

12. Standard configuration of electrical protection class IP40

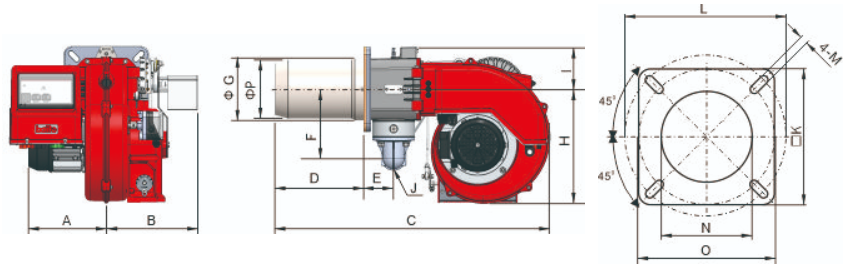

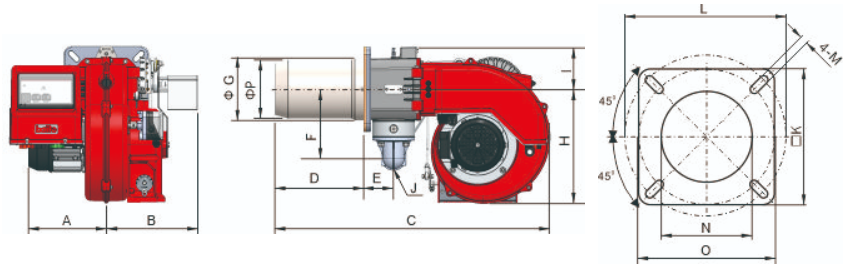

日本 Olympia Original Dimensions

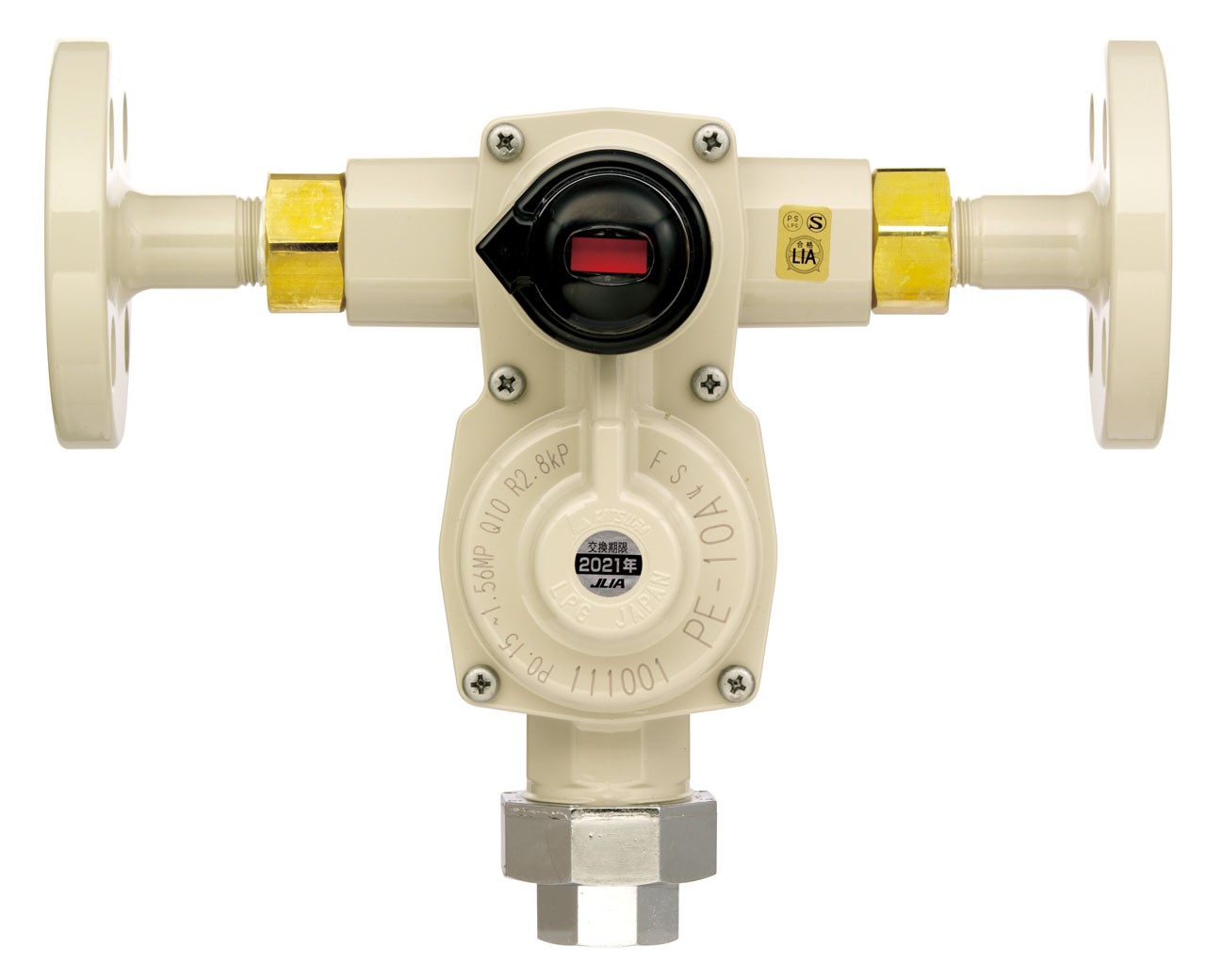

-可調壓差式 蒸汽專用.jpg)

-可調壓差式.jpg)

-固定壓差式 水、油、空氣.jpg)

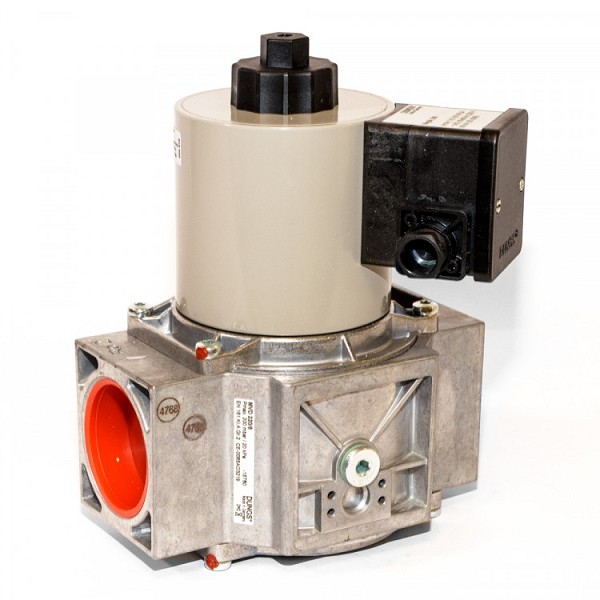

.jpg)

.jpg)

.jpg)

.jpg)